The 10-Minute Rule for Mhs - Material Handling Supply Inc.

The 10-Minute Rule for Mhs - Material Handling Supply Inc.

Blog Article

What Does Mhs - Material Handling Supply Inc. Mean?

Table of ContentsThe 4-Minute Rule for Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. - QuestionsThe Ultimate Guide To Mhs - Material Handling Supply Inc.The Facts About Mhs - Material Handling Supply Inc. RevealedThe Best Guide To Mhs - Material Handling Supply Inc.Rumored Buzz on Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift rental watkinsville, ga. If all-time low of this line goes beyond the stability triangle due to the fact that a lots is too hefty or expensive, or because the forklift is out a level surface area it will tip over. A vertical line prolonging from the center of gravity of the vehicle-load mix need to remain inside the security triangular to avoid the forklift from tippingThe various other principle to understand is the forklifts facility of gravity. When unloaded, the forklifts facility of gravity is best concerning below.

Much heavier tons change the center of gravity ahead also further. Raising the lots also moves the center of mass ahead. In order to stop the lift from tipping, the consolidated center of mass of the lots and the lift must stay inside the stability triangular (at ground degree) in any way times.

An Unbiased View of Mhs - Material Handling Supply Inc.

If you have a balanced tons, the tons is unlikely to influence the side-to-side center of mass. https://linktr.ee/mhsinc30677. Yet if you drive on a sloped surface area, your facility of gravity can pass beyond the security triangle and the lift might tip. Every forklift has a recognition plate that notes vital information about the truck

To be sure that the center of gravity of your forklift stays inside the stability triangular, do not try to lift anything larger than the recognition plate allows. Despite how busy you are, you should check your forklift before using it. If you do discover something that could impact the safety of the car you must report it promptly.

Follow the operators manuals supplied by the equipment manufacturer. These manuals describe the safe procedure and maintenance of forklifts. Bear in mind, the driver is responsible for the secure procedure of the forklift. Do a pre-operation inspection prior to every shift. If the forklift is made use of all the time, examine it either before each change or after each change.

Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

It is completed in two parts: the walk-around inspection, and, the seated evaluation. It's a great concept to have a list to make sure you do not miss out on any type of actions.

Inspect the problem of the tires. If the forklift is an exterior forklift with pneumatically-driven tires, examine the air pressure and search for extreme wear on the tires. A tire with low atmospheric pressure can cause the lift to tip when a tons is raised. So can a tire failing.

An Unbiased View of Mhs - Material Handling Supply Inc.

Seek fractures or other signs of wear. Inspect all liquid degrees. Check the engine for any type of indicators of wear, loosened connections, or leakages. Wipe up any type of too much oil or other combustible compound. Search for fractures or defects in the forks, backrest, pole, and overhanging guard. Check the recognition plate to make certain it is undamaged and understandable.

Beginning the engine. Constantly start the engine while seated in the operator's positionnever while standing along with the forklift. Check all assesses and warning lights, and the battery or gas degree. Get familiar with the controls. Raise and weblink lower the forks, and turn the mast. Make sure that everything works efficiently and is clearly classified.

Mhs - Material Handling Supply Inc. Can Be Fun For Everyone

You'll require to appear the horn at intersections, and anywhere vision is blocked. Inspect the brakes by dispiriting the brake pedal. There should be some resistance. Establish and examine the vehicle parking brake. Check the guiding. A whole lot of play or difficult guiding will certainly lower your control. Relocate the forklift onward a couple of feet.

Look for triggers or fires coming out of the exhaust system. If you discover anything incorrect with the forklift throughout the walk-around or seated evaluation, do not run it until it has been repaired.

Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

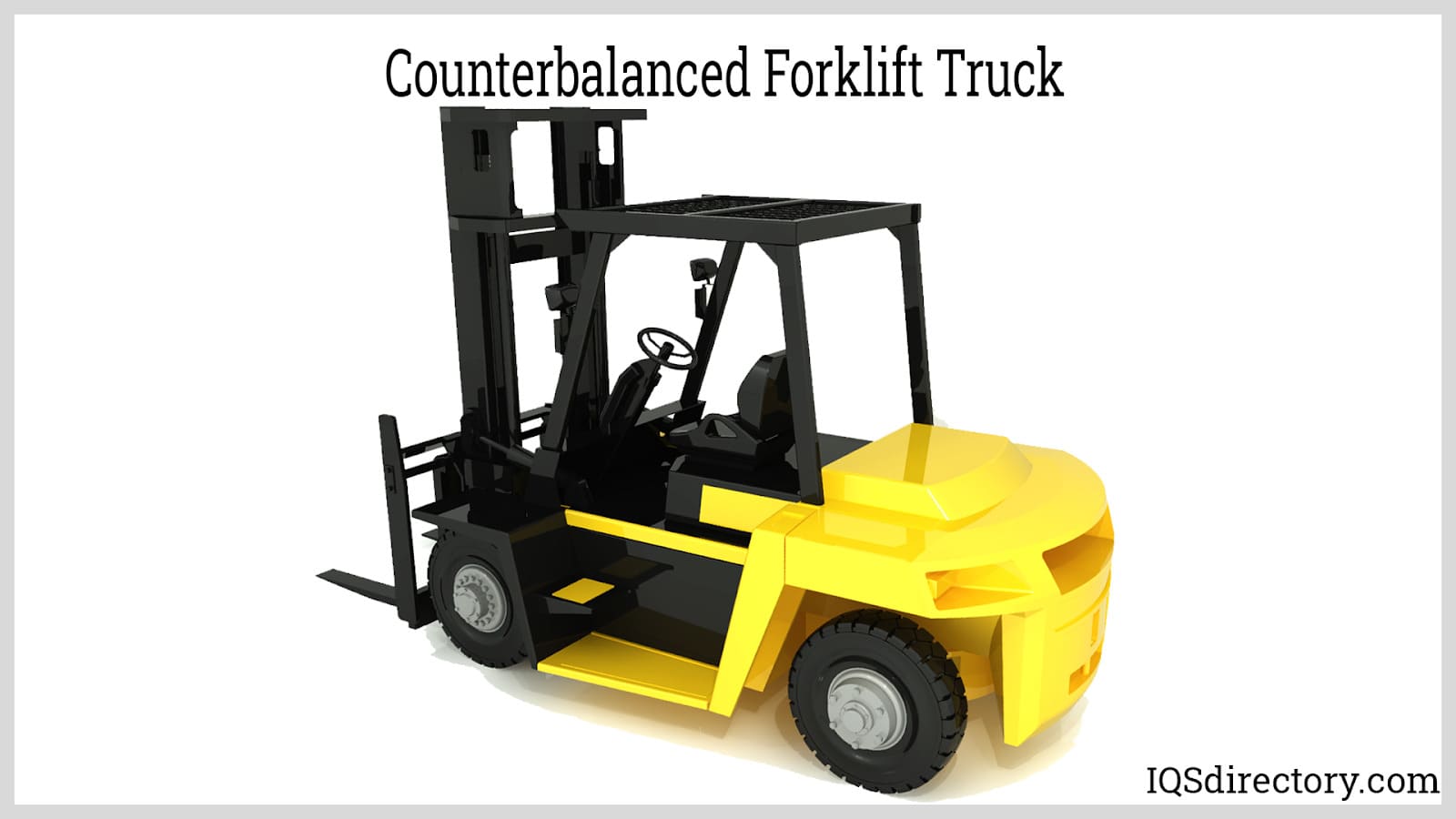

Forklifts have lots of relocating parts and pieces that permit the forklift to operate properly. Recognizing the terminology of the components and composition of a forklift is very important for reliable interaction with others while on the work - https://www.anyflip.com/homepage/gqgot#About. Below are some of the essential functions and parts that comprise the anatomy of a forklift vehicle

For many forklifts, the mast is designed toward the front of a forklift and directly in the forklift driver's line of vision. Forklift masts come with various areas that boost or reduced the forklift carriage along with the forks.

Report this page